Energy-Saving Propeller Boss Cap (Escap) System Returns 5% in Fuel Efficiency

Ahead of the International Maritime Organization’s (IMO) ambitious and challenging goals for 2030 and 2050, the maritime community explores new ways and accelerates its efforts towards decarbonisation and sustainability. Aside from the number one topic of what will be the industry’s fuel of the future – LNG, Hydrogen, Ammonia etc. – there are already options to significantly improve ships’ fuel efficiency, reduce CO2 emissions and protect the marine life.

At Fast Marine Services, we are constantly looking for new technologies that can optimise our clients’ fleet performance and have a positive impact on the marine life and eco-systems. Recently, we performed an underwater Propeller Boss Cap (escap) installation job on one of our client’s 50,000 dwt oil tankers. This very specialised and heavy-duty underwater installation was carried out during the ship’s regular port call here in Singapore, causing no delay to the vessel’s sailing schedule. The expected fuel savings generated through the innovative PBCF design are estimated to be in the range of 3-5% with the same reduction in harmful emissions.

How do we perform the installation of the Propeller Boss Cap (escap)?

Prior to the installation, our experienced divers conducted an underwater hull inspection on the submerged hull, appurtenances and propeller units, checking the vessel’s overall condition.

Preparation for the Installation of the escap

The team onboard the workboat prepares and sets up all relevant tools, required in the installation process. These include new lock wire, bolts, wrenches and washers. A gasket is then glued onto the PBCF in order to fill uneven spaces between PBCF and the propeller hub. This mechanical seal prevents leakage from or into the joined objects while under compression.

Removal of the original Propeller Boss Cap (PBC)

The process firstly requires the removal of the cement or epoxy filling from the bolt pockets on the perimeter of the Propeller Boss Cap. The bolts around the cap are then removed to separate the cap from the propeller hub. Once the Propeller Boss Cap is clear, it is removed by the workboat’s crane and lifted to a designated storage area on deck.

Installment of the escap

After removal of the original Propeller Boss Cap, the crane lowers the new PBCF into position behind the propeller and the divers align its position with the propeller hub. Once positioned correctly at the 12 o’clock mark, the diver progressively tightens the bolts in the prescribed pattern. The surface team then starts pumping grease into the PBCF and prepares the cement or epoxy according to the manufacturer’s instructions. Exact portions of the cement or epoxy are then supplied to the diver. The ecologically compatible grease works as a lubricant to lower the friction resistance of the propeller.

What is the Propeller Boss Cap (escap) System

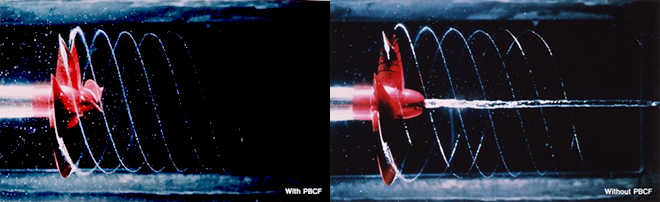

Propeller Boss Cap Fins System, PBCF in short, is an energy-saving device attached to the propeller of a vessel. PBCF was invented by Mitsui OSK Lines Techno-Trade’s (MOL Tech), which recently won an award for its environmental impact-reducing technology. The device breaks up the hub vortex generated behind the rotating propeller, which improves propulsive efficiency by recovering the energy loss.

Features/Benefits of Propeller Boss Cap (escap)

The instalment can be conducted anytime without waiting for vessel’s going into dry-docking. The owner of the vessel can enjoy the benefits immediately after performing the PBCF installation on-site and underwater.

Fuel Efficiency

The innovation returns between a 3-5% reduction in fuel consumption, resulting in substantial cost-saving and the decrease of CO2 emissions per year.

Easy Installation

No hull modification is needed. The process is simply by removing the existing propeller boss cap and replace it with the PBCF.

Maintenance Free

Since the PBCF is not a moving part, regular maintenance is not required. Inspection and polishing can be conducted wither during the vessels’ dry-docking or during regular underwater inspections and maintenance. The performance of the device does not decline over time since it doesn’t require an engine.

Custom-Made

Each PBCF is designed and optimised for the shape of the vessel’s propeller. There is no standard size and it requires an advance order three to four months prior to the installation date.

Immediate Effect

The owner of the vessel can enjoy the benefits immediately after installation.

Environmentally Friendly

CO2 emissions can significantly be reduced with the implementation of PBCF. The advanced version of the PBCF can further reduce vibration in the stern and lower underwater noise, contributing to the protection of the marine life and ecosystem.

If we have sparked your interest in PBCF installations, please get in touch for more information or a bespoke quotation. Fast Marine Services also offers a wide range of other specialist underwater repair and maintenance services for your assets in Turkey.

PBCF #pbcf